OUR SERVICES

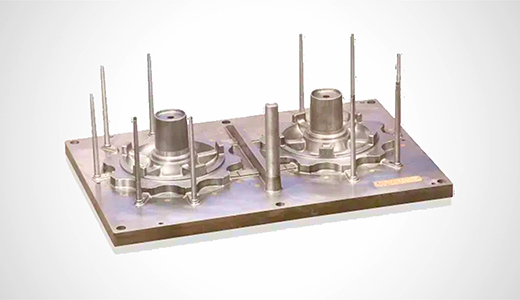

Pattern & Tooling Solutions

KOOT specializes in developing high-quality tooling solutions for parts crafted from diverse materials. Our services include comprehensive tool maintenance with NDA and IP protection.

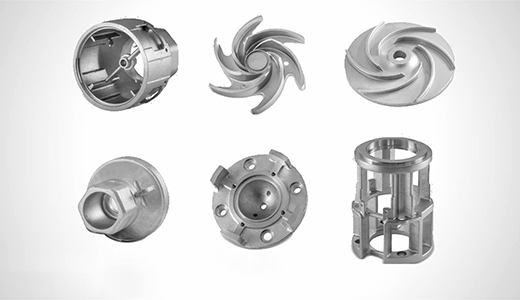

Ferrous and Non-Ferrous Castings

With a network of over 600 foundry partners and ownership of two group-owned foundries, we specialize in selecting the ideal foundry to achieve the required quality and surface finish for components.

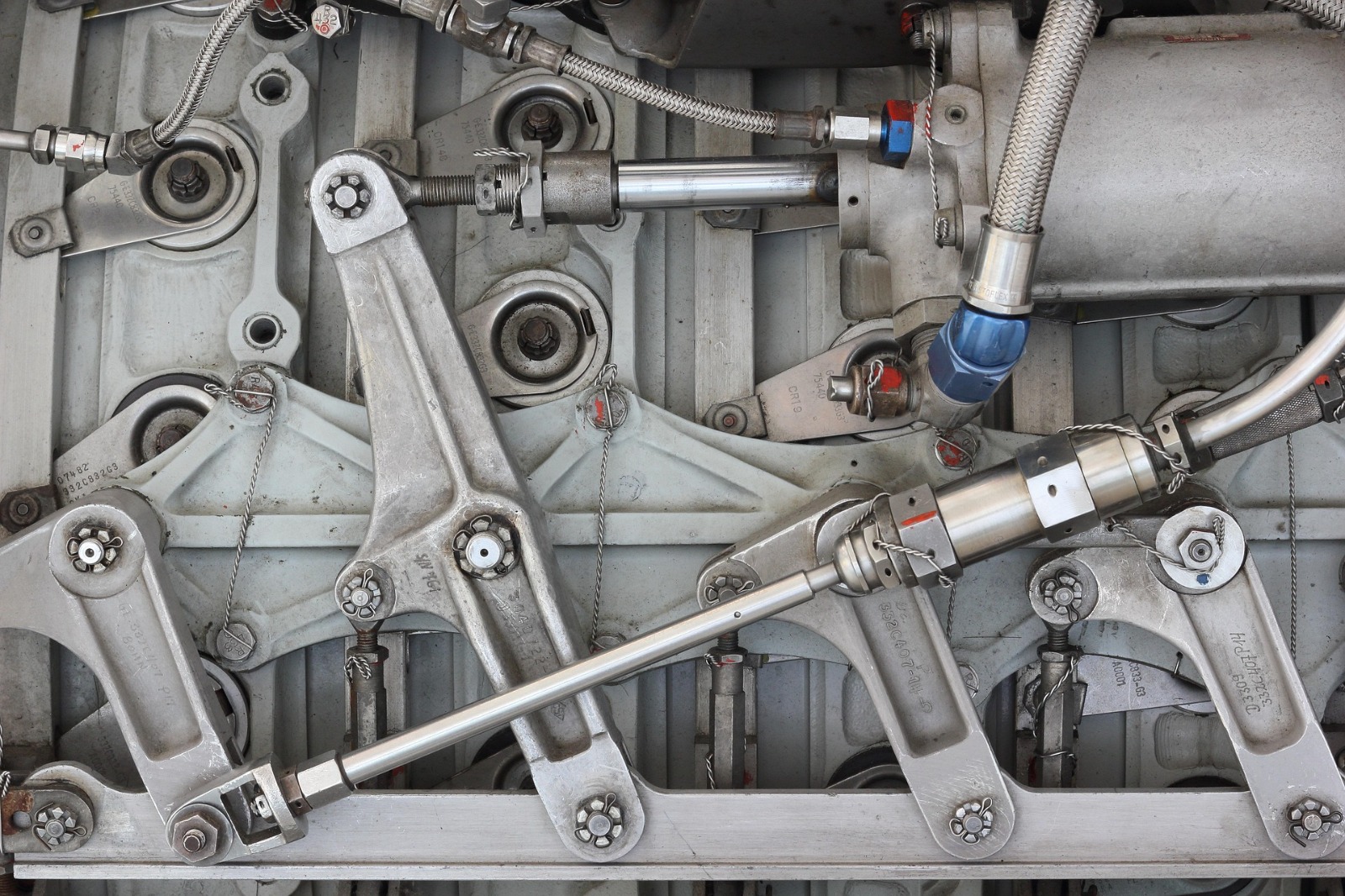

Intricate Investment Castings

We excel in producing precision investment castings for intricate pump , motor and valve components.

Forged Parts

We specialize in crafting tailor-made forged parts known for their exceptional strength and durability, such as pump and motor shafts.

Die Castings

We specialize in precision die-casting for pump and motor housings, and rotors, ensuring durability and precision to meet global industry standards.

Sheet Metal Fabrication

Our capabilities include sheet metal fabrication of impellers, casings, and motor housings, utilizing precision welding techniques tailored for our focus industries.

Plastics & Elastomer Molding

KOOT provides a wide variety of rubber and plastic components specifically designed for pumps , valves & motors, crafted using state-of- the-art injection molding machines.

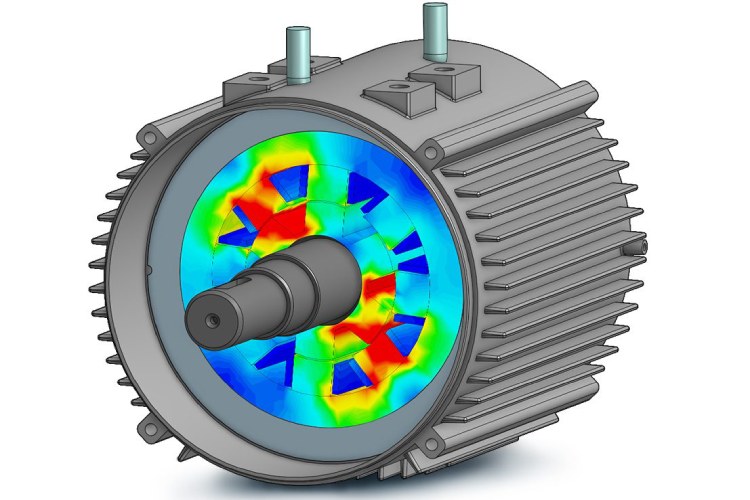

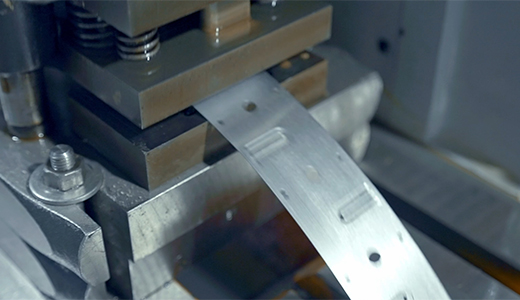

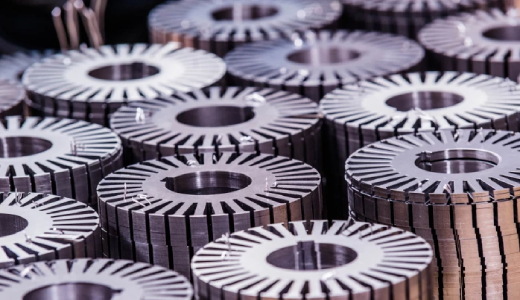

Motor Stamping

We leverage advanced electrolamination stamping technology to optimize motor efficiency and streamline the production of rotors and stators.

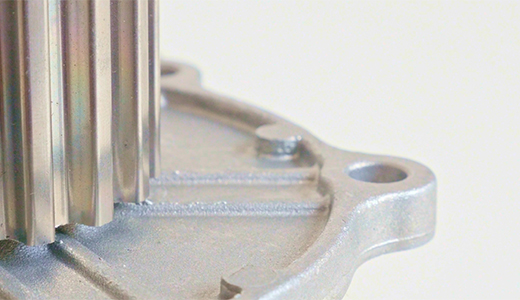

Precision Machining

Our advanced machining division utilizes over 50+ state-of-the-art CNC machines from Japan, Germany, and Korea to deliver precision- machined components with high tolerance levels to pump , valves , compressor , motor and cross industry manufacturers in over 25+ countries worldwide.

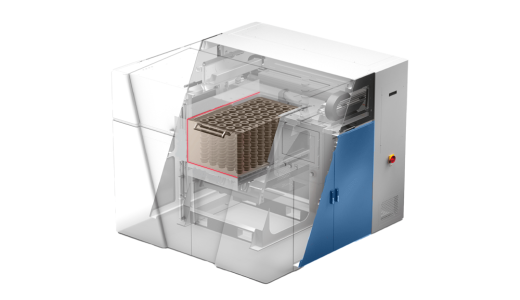

3D Printing & Prototyping

Our center provides comprehensive Rapid Prototyping services with 3D printers using PU materials for product brainstorming and process testing. Specializing in Rapid Prototyping, Innovative Re-engineering, and Rapid Tooling, we support industries from concept to production.

Metal printing

Our partner facility features a 3D sand printer for rapid prototyping and the production of high-quality, intricate cores and castings.

Advanced Coating Solutions

Our Coating department provides a range of corrosion-inhibiting coatings under one roof, including Powder Coatings, Fusion Bonded Epoxy (FBE), Rilasn, Liquid Coatings, and automated ED Coatings.

Motor Winding Services

We offer hand-wound and machine-wound services for pump and motor manufacturers, using high-quality materials to meet strict standards.

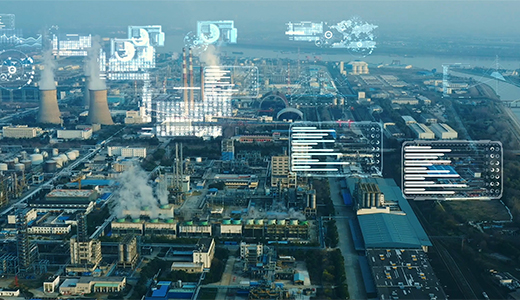

IoT and Electronics Integration

KOOT exports IoT-enabled pumps, motors, and motor controllers with integrated electronics to leading manufacturers in America and Europe.

Quality Assurance Services

At KOOT, our ISO 9712 Level II & III inspectors ensure thorough inspection across all services, including factory audits, pre-shipment checks, and production monitoring for meticulous quality assurance.

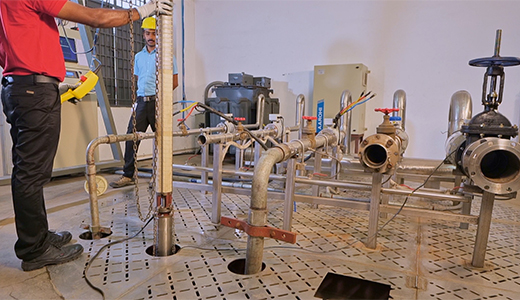

Testing & Validation

Utilize our advanced hydraulic pump and electrical motor testing facilities to expedite your product testing process. Our expert engineers and state-of-the-art labs are dedicated to accelerating your product development cycle.Design Competence

Industrial design

KOOT’s Industrial Design team focuses on creating innovative, user-friendly, and efficient solutions for pumps, motors, and valves. With a deep understanding of ergonomics, functionality, and aesthetics, the team designs products that meet industry standards while ensuring ease of use, durability, optimal performance, and striking visual appeal.

Mechanical design

KOOT specializes in the mechanical design of pumps, motors, and valves, utilizing advanced simulation and modelling tools to guarantee high performance and long- lasting durability. The team integrates cutting-edge mechanical engineering practices to design robust systems tailored to meet the specific needs of each customer.

Hydraulics Engineering

Hydraulics play a crucial role in KOOT’s offerings. Expert engineers design hydraulic systems for pump casings, impellers, and valve functions, ensuring precision and reliability in high-pressure applications. The company excels in developing custom hydraulic solutions that meet the diverse demands of various industries.

Electronics + IoT

KOOT is proficient in integrating advanced electronic controls and automation into pump, motor, and valve systems. This includes sensors, controllers, and smart technologies that improve system efficiency, monitor performance, and enable remote operation. The electronics team ensures that each product meets stringent reliability and safety standards, with state-of-the-art IoT integration to enhance operational intelligence.

Materials technologies

KOOT leverages the latest advancements in materials science to create durable, corrosion-resistant pumps, motors, and valves. The company carefully selects and tests materials that enhance product lifespan, performance, and resistance to harsh environments, ensuring systems operate efficiently, even under extreme conditions.

Reverse Engineering + Benchmarking

KOOT provides comprehensive reverse engineering services, allowing for the analysis and reproduction of existing pump, motor, and valve systems. This expertise enables the company to improve upon older designs, replace obsolete components, and develop custom solutions to help clients optimize their product ranges, supported by benchmarking for industry-leading performance.